The Spray-Net Process

Our transformative process is more than just a service; it's a meticulously designed journey that begins with an in-depth consultation and concludes with a stunning reveal of your revitalized home. Every step of this journey is marked by precision, expertise, and an unwavering commitment to delivering flawless and long-lasting results.

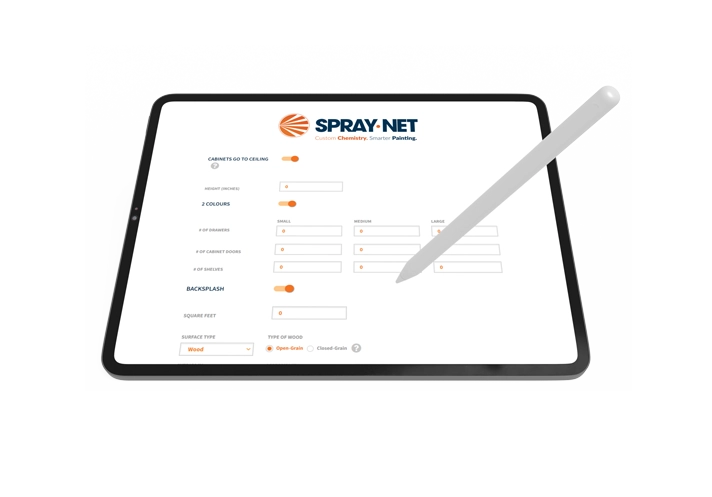

Consultation & Cabinet Evaluation

During your at-home consultation, we'll use our proprietary software to calculate a fixed price for your project, assess cabinet conditions for refinishing, help choose a paint color, and explore cost-effective options within your budget.

Coating Formulation

Once you've chosen your color, we'll begin crafting your custom kitchen cabinet paint, formulated for durable, scratch-resistant, and washable results, offering the benefits of brand-new cabinets in paint form.

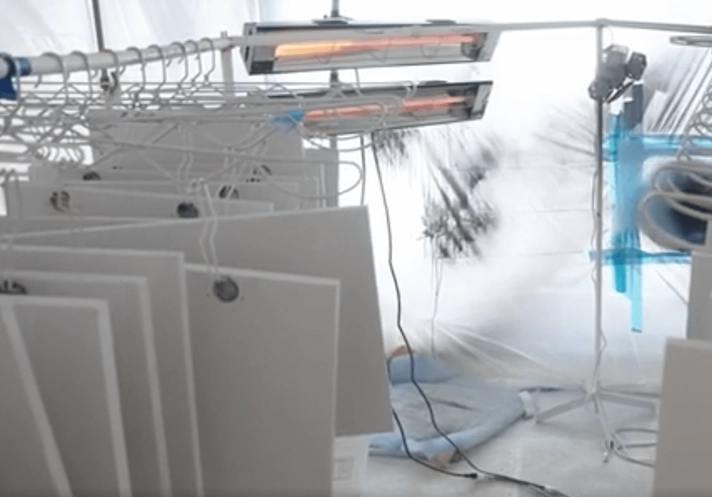

Spray-Booth Set-Up

On revamp day, our in-home ventilated spray booth with drying racks and infrared lamps ensures efficient and mess-free kitchen cabinet preparation, painting, and drying, guaranteeing a swift transformation without prolonged disruption.

Remove Cabinets & Hardware

Next, we’ll remove all kitchen cabinets doors, drawers, and hardware so we can get started on masking and surface preparation.

Mask & Protect All Surfaces

We protect all non-painted surfaces, including ceilings, floors, backsplash, appliances, and countertops during painting. If cabinets won't be painted inside, there's no need to empty them; we'll mask and seal to prevent dust or debris.

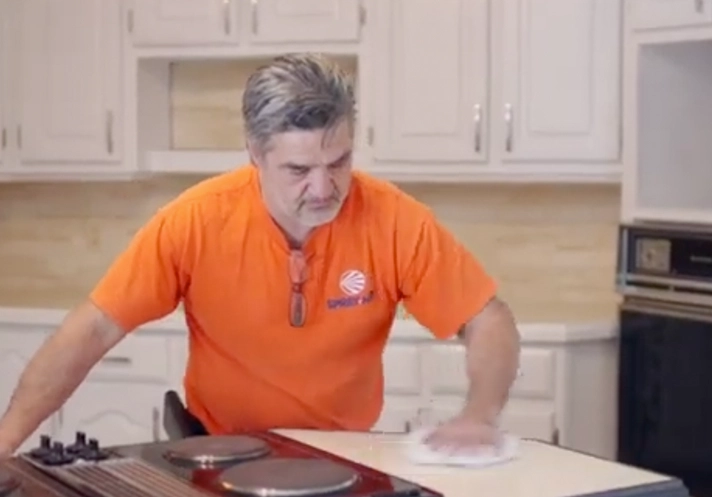

Surface Preparation and Repairs

We meticulously prep all surfaces by degreasing, scuffing, and sanding. We use our ultra-thick grain filler to repair scratches and fill deep-set grain. We vacuum up all dust to ensure a clean surface and finish the preparation process by using our proprietary cleansing solution for optimal coating adhesion.

Prime All Surfaces

Next, we use our proprietary and custom-formulated, high-build primer to promote maximum adhesion, ensure flawless and uniform color coverage, and stop any tannin bleed (a common occurrence when painting hardwoods).

Spray Paint Application

Experience the magic as we apply our water-based, odorless 2-component polyurethane coating to your kitchen cabinet boxes and doors using a suspended spraying rack, achieving a smooth, streak-free finish that will make you question why you ever considered cabinet replacement!

Dry and Cure

Our spray booth is equipped with infrared lamps to accelerate the drying and curing of our kitchen cabinet paint. By the time we leave your home, your cabinets will be dry to the touch and ready to use with care.

Clean-up

Lastly, we take down our spray booth, reinstall all cabinet doors and hardware and conduct a final and thorough clean-up. The only thing we’ll leave behind is a set of Spray-Net mugs so you can enjoy your first morning coffee in your new kitchen Spray-Net style!